Simulations For Operator Training

boilers - turbines - chemical plants - pulp/paper mills - lime kilns - hydroelectric - etc.

DCS - SCADA - Process Control - Manual Panels - Continuous - Batch - Real Time - etc.

|

|

< and everything in-between > |

|

When you cannot find what you need:

We provide simulations for your training needs. The simulations look and act like your equipment. For dcs/scada systems, displays look exactly the same, alarms work, and first-principle models drive the numbers. For manual panels, dials move as they should based off the models; lights and switches work. Both types come with robust support for the trainer. The simulations use standard pc equipment.

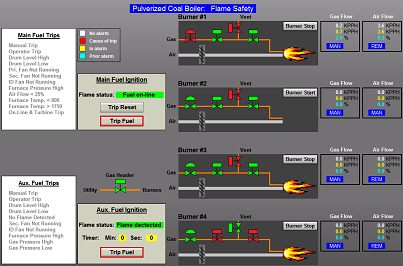

1. Distributed Control Systems (dcs)

Distributed control systems can get quite large. Our simulations can handle them. Alarms, trends, etc. are supported. The displays and process look and act like your own. We support multiple monitors. If the operator has multiple workstaions with the actual system, he can have the same with the simulation. We use complex first-principle models.

2. Legacy (older equipment and processes)

There is some old stuff out there. You may have some of it. The equipment works. You could replace it, but cost justifying new equipment that won't cost less to operate or increase quality? Often hard to do. The problem with legacy gear and processes is teaching new people how to run the equipment or process. We can handle older plc's and very old manual panels. Frequently with older gear, there are process sounds that clue a knowledgeable operator to equipment and process conditions. We can take recordings of those sounds and incorporate them into the simulation for the appropriate conditions. Mostly, though, older equipment deals with manual panels. For more information on manual panels, Click here.

3. Multiple Windows / Displays

With our package, a trainee may have as many monitors or computers as needed. You may have two trainees working cooperatively or independently. You may have a trainer monitor a trainee and have special options for causing upsets. For large manual control panels, you can have two or more monitors side-by-side with the panel laid out on them.

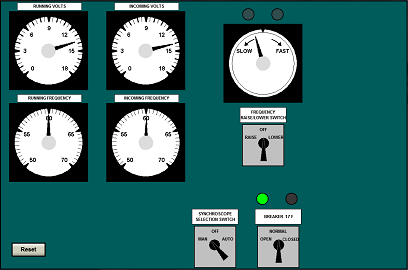

4. Manual PanelsMany processes do not require digital control or work too well to justify the cost of going digital. We can provide traing simulations for your situation. No matter how large or complex your control panels, no matter how complex your process, we can provide you a simulation to fit your needs. The synchroscope download will serve as an example. It has dials, switches, and lights. It runs real-time. It is modelled on an actual process. For large panels, a customer can use multiple monitors or a single monitor that the user can move around the panel. |

|

|

|

|

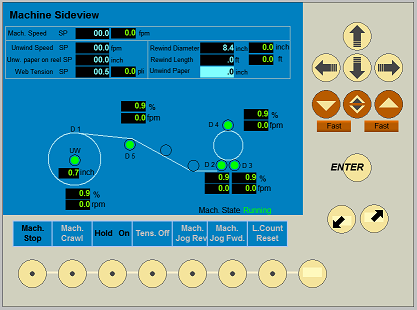

5. PLC'sYou may have a plc controlled process or even more likely a plc system combined with one or more manual panels. We can provide a simulation for this situation. The image shows part of a process control panel from a simulation, one driven by a plc. The control panel also consists of many manual switchs and lights etc (not shown). Your simulation would run real-time, the numbers would be accurate, and a trainee could learn without disturbing the actual system. |

|

|

|

|

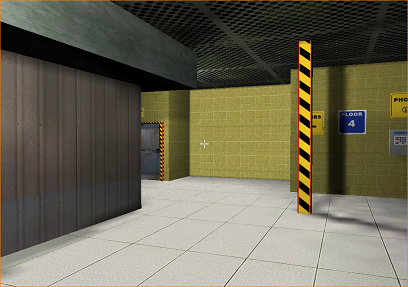

7. 3DYou may have need of 3D training. We can incorporate our process models into 3D scenarios. With most young people familiar with interactive 3D, it becomes a viable training method when you have to replace retiring experienced operators. |

|

8. Sounds

People notice sounds even when not paying attention. When it comes to running processes or equipment, sounds play a large role. Some control rooms are very isolated, but even for those, when a high pressure safety lifts its sound goes through the walls and gets the attention of the operators. For everybody else, closer to the situation, sounds can frequently tell more about current conditions than displays or lights. Older operator keep one ear attuned to the process sounds all the time.

Our simulations can incorporate sounds for the proper conditions. These included sounds have presence. The more senses that come into play, the better the training. In addition to improving the training package, the use of sounds does a lot to make a trainee pay attention. Day to day we live in a sound-proof environment; when outside many people have earphones in their ears. Unusual noises during training? The trainee pays attention. This is what you want.

9. Versus the Competion

Our competition consists of companies that sell control equipment and systems. Simulations become an add-on to their primary product, but nothing is allowed to interfere with that product's main purpose, which is control, not training. You go to them for control systems, not training simulations.

We sell simulations for training operators. That is our product. Our simulations look and act like your system, are designed for training, and are flexible for future changes to the process and changing training needs.

We are simply the better choice. We are cheaper and our product far more flexible. We handle simulations for different types of control sytems, older and discontinued systems, and combinations of control systems and manual panels. For a large facility with a variety of training simulation needs, we provide one-stop shopping.

For companies with multiple facilities, we provide an organized way to have standard, consistent simulations across your organization.

10. Training Options

With the following features, your trainer gets complete flexibility for training.

10a. Saves, Loads, & Scenarios

With our package you can create as many scenarios as desired. Your trainer runs the simulation until it is in a particular state, for example 'down cold'. She stops the simulation. She schedules a fault to occur in 15 minutes. She saves it and calls it Start-Up Scenario #1. In the future a trainee can load and start that scenario, follow the normal start-up sequence, and 15 minutes into the session an equipment fault occurs. How does the trainee handle it?

10b. Faults, Failures, & Upsets

In normal training, a trainee who can do a complete start-up and a complete shutdown has mastered 80-90% of the job. After that comes idiosyncracies of the process, procedures for special situations, recovering from process upsets, and dealing with problems before they upset the process. Our simulations support device failure (won't start, stop, etc.), sensor failure (fails high, fails low, fails at current value, drifts, etc.), inventory quality problems, environmental conditions, mechanical failure (pipe ruptures, tank leaks, etc.), and others.

10c. Trainer's Computer

The computer running the simulation may be the one the student uses or one set aside for the trainer. In the latter case the trainer can watch the trainee's process and make comments or cause a problem immediately or a short time in the future. The trainer can also act as a field helper for the trainee.

10d. Grading

Our simulations support grading performance in two ways. As with any process, the truth is told in the trends. An instructor looking at the trends can see exactly what happened. We can also include grading based on actions that do not appear in the trends. When shutting down, for example, a tank may drop below a given level causing the level controller to close off. Proper procedure for the shutdown may also include turning off the pump and putting the controller in manual with a zero output. These latter actions would not show up in trends, but they are something that would determine whether the trainee had properly accomplished the shutdown.

10e. Built-In Documentation

We can provide training documenation built into your simulation. You can also change the text of the documentation without changing the entire package.

|

Download Simulations |

JHA Simulations, Inc. - (313) 887-1337 - info@jhasimulations.com